1.OEM, ODM service. (We can customize the molds, appearance, structure, surface finishing, color, packaging.)

2.The OEM, ODM design are not the same as other industries.

In the middle of 2017, a man came to Wiscoo, bringing only one piece of hand drawing, and this man is one of our longtime customers who we had made business with for more than 5 years. But after talking, he told us that he didn't come for his own business but stand for TMA company this time.

There are three members in this company: Tommy, Monica, Art. All of them are very successful brand owners in CBD industry in California for many years, and they are our long term cooperation customers.

They had something in common. They were not satisfied with current CBD vaporizer device in the CBD market, so they gathered together and committed to visiting and researching the supplier side of CBD oil from 2014. Finally, they had an idea and hoped we could help them promote this into CBD market.

Then TMA was found as the company name which was short for their names and base on the first letter of their names.

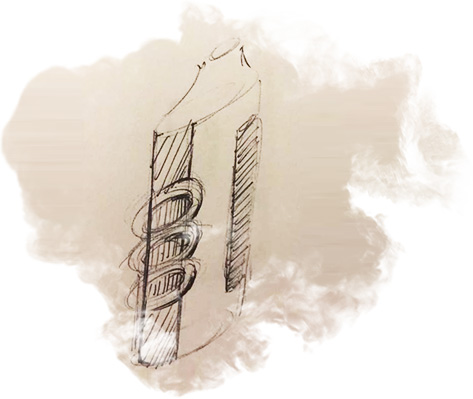

At the first sight we saw the hand drawing, we were shocked by its small and delicate design, we had to say it was amazing. That is a cigarette lighter look, not the same as our natural cylinder-shaped design. So there will have some limitation for the size of the inside structure, the size of battery cells, the size of cartridge inside. As we have many other projects on hand at the same time, we do not have professional engineers to follow up with this case. After have discussed with our team for many times, we agreed that this was a valuable project, so we set up a team special for this project.

When we started this project, we found that there are too many things that needed confirming with both sides for the first two months, and we had skype meeting to discuss the structural modification, property everyday.

Then the first batch samples came out, and TMA partners took some samples and was back to California where there were most of CBD vendors in. We would like to get some feedback from the market, and we were very pleased that people there hurrahed to this design which strengthened our confidence a lot.

As the entire product is very small, the filling port is one of the difficulties to us. And we need to plug the silicone into the inner cartridge from a hole, the silicone which is for preventing leaking oil is tiny, so we need to make them convenient not only for automatic oil filling machine, but also for hand filling. We discussed a whole day, then we had a conclusion that we can use tweezes help to pull the silicone into the cartridge hole. But as it's very slim, we can not use the clip to hold the silicone as usual, so we had an urgent meeting with our filling machine supplier in that afternoon, they suggested us to do a vacuum plant instead of clipping to hold the silicone. We came to filling machine factory on the second day to see how the machine works, and confirmed the vacuum filling machine finally.

At this time everything was confirmed, we visited some mold factories together, and choose a best from them, it took us 6 weeks to open a new mold and get the first samples.

We took the first samples to an American show, it's a big success, we won a million orders there.

After 20 days, the first batch of mass production products had been sent out, customers got them after 5 days. Then we get more and more orders since then.

This is a true story between TMA company and Wiscoo.

Copyright © Wiscoo Electronics Company Limited All Rights Reserved | Sitemap